Product Description

NEW POWER is one of the leading and professional manufacturers of sectional warping machines in China. Our SGE342 series high-speed sectional warper for striped warp yarns is high-end equipment specially developed for complex stripes, plaids, and multi-color warp-knitted fabrics. It integrates high-speed operation, intelligent control, and precise slitting, and is suitable for the warping needs of natural fibers, chemical fiber filaments, acrylic, cotton yarn, blended, and special yarns. Modular design and advanced technology, help customers improve warp quality, reduce production costs, and meet the diversified needs of fast fashion and industrial textiles. Our sectional warping machine is the best-supporting equipment for high-speed warp knitting machines.

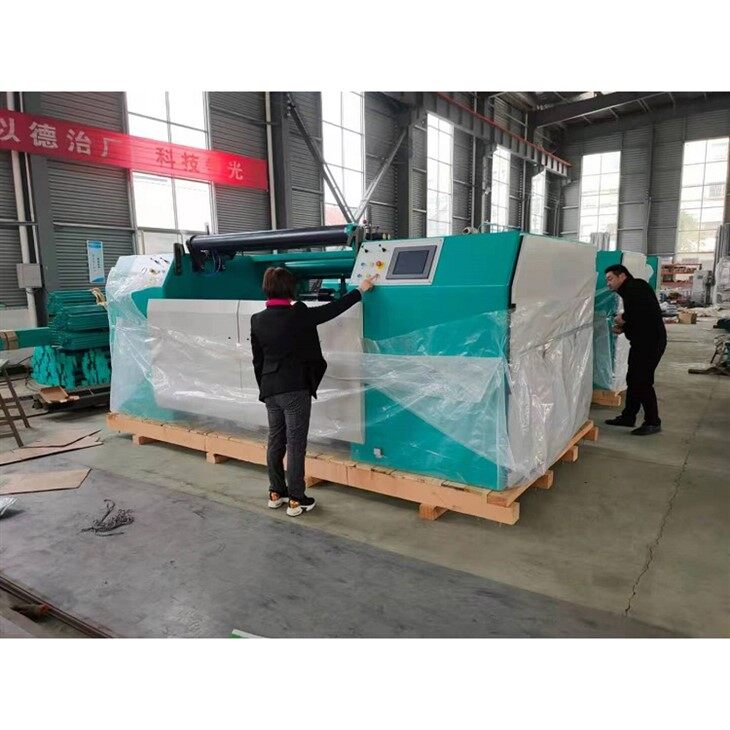

We are Sectional Warper experts

NEW POWER is one of the leading and professional manufacturers of sectional warpers and offers products and services of exceptional quality.

Designed for high-quality warp knitted fabrics, empowering global textile companies.

Precise sectional

Efficient production

Intelligent control

Technical Specification

| Product Name | Sectional Warper For Striped Warp Yarns |

| Model | SGE342 |

| Beam Size | φ55"×42", φ40"×42" |

| Warping Speed | 50-800m/min |

| Electricity Main Power | 15 Frequency motor |

| Tension Roller Motor | 5W Frequency motors |

| Yarn Storage Length | ≤10 meters |

| Copy Precision |

a. Circular number same b. Perimeter |

| Maximum Length Record | No limitation by computer |

| Spindle Pitch | 400*400mm(custom-tailor) |

| Total Ending | 936 (600-1800 According to requirement) |

product Core advantages

Precise Sectional Warping technology

* Intelligent sectional system: adopts high-precision slitting reed and digital positioning technology to ensure that the stripe width error is ≤0.1mm, perfectly matching the requirements of complex pattern design.

* Multi-color yarn synchronization control: supports 8-12 color yarn synchronous slitting, automatically aligns the color yarn position, avoids color difference deviation, and improves the beauty of the fabric.

High-speed and efficient production

* Ultra-high-speed winding: frequency conversion motor drive, the maximum operating speed is 800m/min, the production capacity is increased by more than 30%, and the demand for large-volume orders is met.

* Fast yarn change system: modular yarn rack design, yarn change time is shortened by 50%, and different yarn varieties and specifications are seamlessly switched.

Intelligent tension management

* Closed-loop tension control: multi-level electronic sensors monitor in real-time and dynamically adjust yarn tension, with a difference of <±3%, which greatly reduces the breakage rate (≤0.5 times/10,000 meters).

* Automatic stop and positioning of yarn breakage: photoelectric detection + sound and light alarm, accurately lock the yarn break position within 0.1 seconds and reduce downtime losses.

Flexible and adaptable

* Wide width compatibility: The warp beam width covers 800 mm-2200 mm, suitable for clothing, home textiles, industrial base fabrics, and other fields.

* Multi-material support: Cotton, polyester, spandex, carbon fiber, and other yarns can be stably processed, and process parameters can be switched with one click.

Energy saving and stability

* Energy-saving drive system: frequency conversion technology + energy feedback device, energy consumption is reduced by 30%, in line with EU CE energy efficiency standards.

* High rigidity structure: aviation-grade alloy frame + precision bearing, anti-vibration design ensures long-term high-speed and stable operation.

Intelligent operation

* Human-machine interaction interface: 10-inch touch screen, supports multi-language switching (Chinese/English, etc.), one-click storage, and call of process parameters.

* Remote monitoring: Optional IoT module, real-time transmission of production data to mobile phones/computers, remote operation and maintenance, and fault diagnosis.

Application scenarios

Clothing fabrics

Striped shirts, plaid suits, sportswear elastic warp yarns.

01

Home textile decoration

Jacquard curtains, multi-color bedding, digital printing base fabrics.

02

Industrial textiles

Automotive interiors, filter cloths, geogrids.

03

Special materials

Carbon fiber composite materials, anti-static workwear fabrics.

04

why choose us

15+ years of technical accumulation

Deeply cultivating the field of textile machinery, serving customers in 50+ countries around the world.

Customized service

Provide equipment configuration, process training, and after-sales support according to needs.

Fast delivery

Standardized production + intelligent warehousing, shortening the delivery cycle by 30%.

Worry-free after-sales

24-hour online response worldwide, lifelong technical support.

Welcome to buy high-quality sectional warper for striped warp yarns. We provide you with factory prices, satisfactory services and timely delivery. We look forward to your contact.